Medical Cylinders

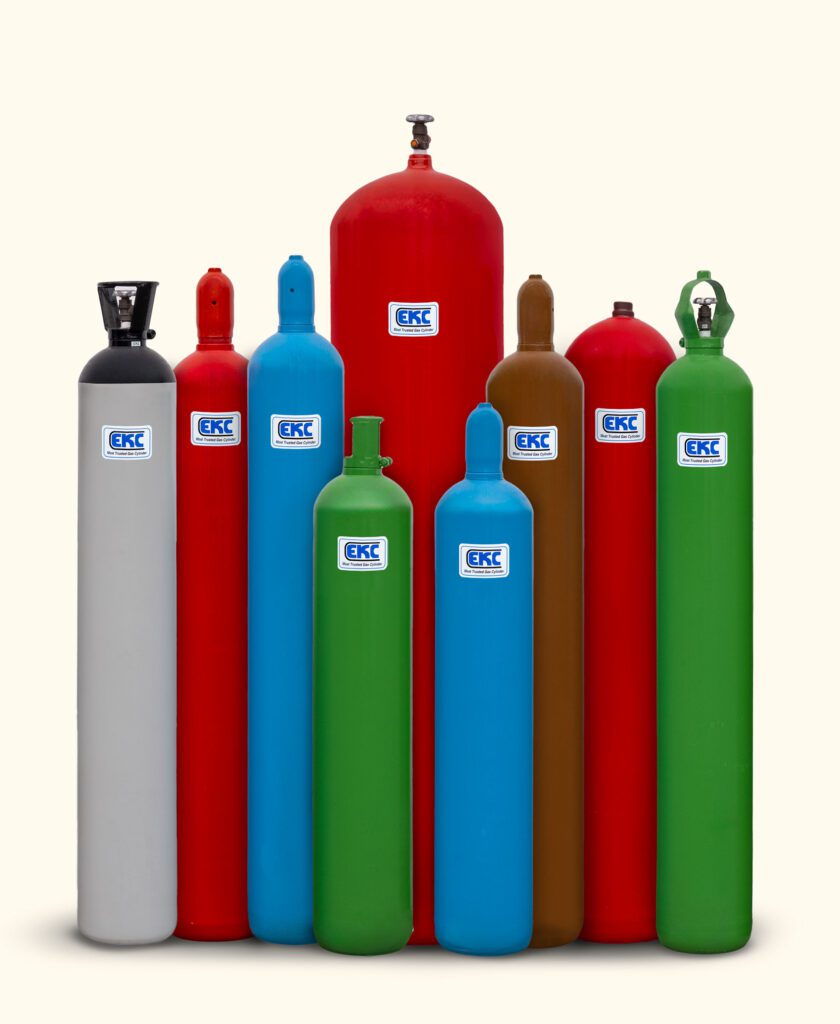

EKC Dubai manufactures a wide range of cylinders specifically designed for industrial gases, medical, food and beverage and fire protection equipment industries. EKC International’s high-pressure cylinders are preferred worldwide for their high quality, long life, aesthetic looks and flexibility to match any kind of international specifications.

EKC cylinders for medical gases adhere to the most stringent regulations, both national and international and are manufactured according to various standards including ISO 9809-1, ISO 9809-2, ISO 9809-3, PED 97/23/EC, TPED (2010/35/EU), IS 7285, EN-1964, DOT & UN ISO and any other international standard.

At EKC Dubai, our aim is to fulfil all customers’ expectations by providing solutions for all their needs. This page provides the customer with information of the most popular cylinders meant for various industrial and medical applications. Further information and intricate details will be provided on request.

Applications of medical gas cylinders

- Use for Oxygen

- Use for Carbon Dioxide

- Use for Nitrogen

- Use for Nitrous Oxide

Oxygen Cylinder

Pressure Gauge

Oxygen Output

Flow meter

Humidifier Cup

Pressure Regulator

Cylinder Valve

Industrial Cylinders

EKC manufactures a wide range of industrial gas cylinders specifically designed for industrial usage, food and beverage. Gases commonly used at Oxygen, Nitrogen, Argon, High Purity Gases etc. EKC high pressure cylinders are preferred worldwide for their quality, aesthetic looks as well as the flexibility to match any kind of specifications.

EKC high pressure cylinders adhere to the most stringent regulations, both national and international and are manufactured according to ISO 9809-1 & ISO 9809-2, PED 97/23/EC, TPED (2010/35/EU), ISO 9809-3,IS 7285, EN-1964 and any other international standard.

At EKC, our aim is to fulfill all customer expectations providing solutions for all their needs. This leaflet provides the customer with information of the most popular cylinders meant for various industrial applications. Further information and intricate details will be provided on request.

Specification for Industrial Cylinders

EKC Industrial cylinders are available for following applications:

- Cylinders for Inert gases

- Medical gases

- Cylinders for Hydrogen gas

- Cylinders for Co2 & fire fight gases

- Cylinders for Helium gas

- Cylinders for Scuba Diving & breathing apparatus.

Criteria for cylinder selection

Industrial Cylinders are selected based on following requirement:

- Working pressure

- Test Pressure

- Manufacturing Standards

- Neck Thread details

- Color Coding

- Certification requirement

GAS CYLINDERS DIAMETER

| Water Capacity (L) | Diameter (mm) | Length (mm) | Weight (kg) | Gas Capacity (Cu.m) | Bottom Shape | Working Pressure (Bar) | Test Pressure (Bar) |

| 1.7 | 102 | 293 | 2.3 | 0.3 | CONCAVE | 200 | 300 |

| 2.0 | 102 | 330 | 2.5 | 0.4 | CONCAVE | 200 | 300 |

| 3.0 | 102 | 470 | 3.3 | 0.6 | CONCAVE | 200 | 300 |

| 3.5 | 102 | 535 | 3.7 | 0.7 | CONCAVE | 200 | 300 |

| 4.0 | 102 | 605 | 4.1 | 0.8 | CONCAVE | 200 | 300 |

| 5.0 | 102 | 745 | 4.9 | 1.0 | CONCAVE | 200 | 300 |

| 1.5 | 108 | 285 | 3 | 0.2 | CONCAVE | 150 | 225 |

| 2.0 | 108 | 340 | 5 | 0.3 | CONCAVE | 150 | 225 |

| 3.0 | 108 | 470 | 6 | 0.5 | CONCAVE | 150 | 225 |

| 4.0 | 108 | 605 | 8 | 0.6 | CONCAVE | 150 | 225 |

| 5.0 | 108 | 795 | 9 | 0.8 | CONCAVE | 150 | 225 |

| 3.4 | 140 | 320 | 5 | 0.7 | CONCAVE | 200 | 300 |

| 4.0 | 140 | 360 | 5 | 0.8 | CONCAVE | 200 | 300 |

| 5.0 | 140 | 435 | 6 | 1.0 | CONCAVE | 200 | 300 |

| 6.0 | 140 | 505 | 7 | 1.2 | CONCAVE | 200 | 300 |

| 6.8 | 140 | 565 | 7 | 1.4 | CONCAVE | 200 | 300 |

| 10.0 | 140 | 795 | 9 | 2 | CONCAVE | 200 | 300 |

| 10.5 | 140 | 830 | 10 | 2.1 | CONCAVE | 200 | 300 |

| 13.5 | 140 | 1045 | 12 | 2.7 | CONCAVE | 200 | 300 |

| 15.0 | 140 | 1155 | 14 | 3 | CONCAVE | 200 | 300 |

| 3.0 | 140 | 310 | 7 | 0.5 | CONCAVE | 150 | 225 |

| 4.5 | 140 | 425 | 9 | 0.7 | CONCAVE | 150 | 225 |

| 5.0 | 140 | 465 | 10.0 | 0.8 | CONCAVE | 150 | 225 |

| 6.8 | 140 | 610 | 12 | 1.0 | CONCAVE | 150 | 225 |

| 10.0 | 140 | 850 | 16 | 1.5 | CONCAVE | 150 | 225 |

| 10.5 | 140 | 885 | 17 | 1.6 | CONCAVE | 150 | 225 |

| 13.5 | 140 | 1115 | 12 | 2.0 | CONCAVE | 150 | 225 |

| 15.0 | 140 | 1230 | 23 | 2.3 | CONCAVE | 150 | 225 |

| 10.0 | 165 | 615 | 14 | 2.0 | CONCAVE | 200 | 300 |

| 14.0 | 165 | 830 | 18 | 2.8 | CONCAVE | 200 | 300 |

| 15.0 | 165 | 880 | 19 | 3 | CONCAVE | 200 | 300 |

| 20.0 | 165 | 1145 | 24 | 4 | CONCAVE | 200 | 300 |

| 13.4 | 203 | 575 | 17 | 2.7 | CONCAVE | 200 | 300 |

| 15.0 | 203 | 630 | 19 | 3 | CONCAVE | 200 | 300 |

| 20.0 | 203 | 800 | 24 | 4 | CONCAVE | 200 | 300 |

| 26.8 | 203 | 1040 | 31 | 5.36 | CONCAVE | 200 | 300 |

| 30.0 | 203 | 1155 | 34 | 6.0 | CONCAVE | 200 | 300 |

| 40.0 | 203 | 1510 | 44 | 8.0 | CONCAVE | 200 | 300 |

| Water Capacity (L) | Diameter (mm) | Length (mm) | Weight (kg) | Gas Capacity (Cu.m) | Bottom Shape | Working Pressure (Bar) | Test Pressure (Bar) |

| 40 | 229 | 1185 | 42 | 8 | CONCAVE | 200 | 300 |

| 46.7 | 229 | 1376 | 49 | 9.3 | CONCAVE | 200 | 300 |

| 50 | 229 | 1470 | 55 | 10 | CONCAVE | 200 | 300 |

| 40 | 229 | 1205 | 48 | 9.2 | CONCAVE | 230 | 345 |

| 45 | 229 | 1345 | 53 | 10.4 | CONCAVE | 230 | 345 |

| 50 | 229 | 1480 | 58 | 11.5 | CONCAVE | 230 | 345 |

| 40 | 229 | 1230 | 57 | 12 | CONCAVE | 300 | 450 |

| 45 | 229 | 1370 | 63 | 13.5 | CONCAVE | 300 | 450 |

| 50 | 229 | 1510 | 69 | 15 | CONCAVE | 300 | 450 |

| 40 | 232 | 1179 | 47 | 6 | CONCAVE | 150 | 225 |

| 46.7 | 232 | 1365 | 54 | 7 | CONCAVE | 150 | 225 |

| 50 | 232 | 1456 | 57 | 7.5 | CONCAVE | 150 | 255 |

| 40 | 267 | 900 | 48 | 6 | CONCAVE | 150 | 225 |

| 50 | 267 | 1100 | 57 | 7.5 | CONCAVE | 150 | 225 |

| 67.5 | 267 | 145 | 73 | 10.1 | CONCAVE | 150 | 225 |

| 75 | 267 | 1605 | 80 | 11.3 | CONCAVE | 150 | 225 |

| 80 | 267 | 1705 | 85 | 12 | CONCAVE | 150 | 225 |

| 40 | 267 | 900 | 48 | 8 | CONCAVE | 200 | 300 |

| 50 | 267 | 1100 | 57 | 10 | CONCAVE | 200 | 300 |

| 67.5 | 267 | 1450 | 73 | 13.5 | CONCAVE | 200 | 300 |

| 80 | 267 | 1705 | 85 | 16 | CONCAVE | 200 | 300 |

| 40 | 267 | 925 | 60 | 12 | CONCAVE | 300 | 450 |

| 50 | 267 | 1140 | 72 | 15 | CONCAVE | 300 | 450 |

| 65 | 267 | 1455 | 88 | 19.5 | CONCAVE | 300 | 450 |

| 80 | 267 | 1765 | 103 | 24 | CONCAVE | 300 | 450 |

| 100 | 267 | 2185 | 126 | 30 | CONCAVE | 300 | 450 |

| 70 | 356 | 920 | 84 | 14 | CONCAVE | 200 | 300 |

| 90 | 356 | 1145 | 100 | 18 | CONCAVE | 200 | 300 |

| 120 | 356 | 1475 | 124 | 24 | CONCAVE | 200 | 300 |

| 150 | 356 | 1820 | 149 | 30 | CONCAVE | 200 | 300 |

| 180 | 356 | 2150 | 173 | 36 | CONCAVE | 200 | 300 |

| 90 | 406 | 950 | 115 | 21 | CONCAVE | 300 | 450 |

| 120 | 406 | 1180 | 138 | 27 | CONCAVE | 300 | 450 |

| 150 | 406 | 1530 | 173 | 36 | CONCAVE | 300 | 450 |

| 180 | 406 | 1880 | 208 | 45 | CONCAVE | 300 | 450 |

| 220 | 406 | 2225 | 243 | 54 | CONCAVE | 300 | 450 |

| 90 | 406 | 900 | 100 | 18 | CONCAVE | 200 | 300 |

| 120 | 406 | 1155 | 123 | 24 | CONCAVE | 200 | 300 |

| 150 | 406 | 1410 | 146 | 30 | CONCAVE | 200 | 300 |

| 180 | 406 | 1670 | 169 | 36 | CONCAVE | 200 | 300 |

| 200 | 406 | 2010 | 200 | 44 | CONCAVE | 200 | 300 |

| 90 | 406 | 945 | 141 | 27 | CONCAVE | 300 | 450 |

| 120 | 406 | 1210 | 173 | 36 | CONCAVE | 300 | 450 |

| 150 | 406 | 1480 | 207 | 45 | CONCAVE | 300 | 450 |

| 180 | 406 | 1745 | 237 | 54 | CONCAVE | 300 | 450 |

| 200 | 406 | 1925 | 266 | 60 | CONCAVE | 300 | 450 |